Methods for Increasing Garri Production Output

Garri, a staple food in many West African countries, holds a crucial place in local diets. As the demand for garri continues to rise, enhancing the production output has become a key concern for processors. The process of increasing output in garri production is a comprehensive one that requires a holistic approach, covering every aspect from the very beginning of raw material selection to the final stages of packaging. By focusing on each stage meticulously, processors can not only increase the quantity of garri produced but also ensure its quality and marketability. Here are some detailed and practical strategies to achieve this goal.

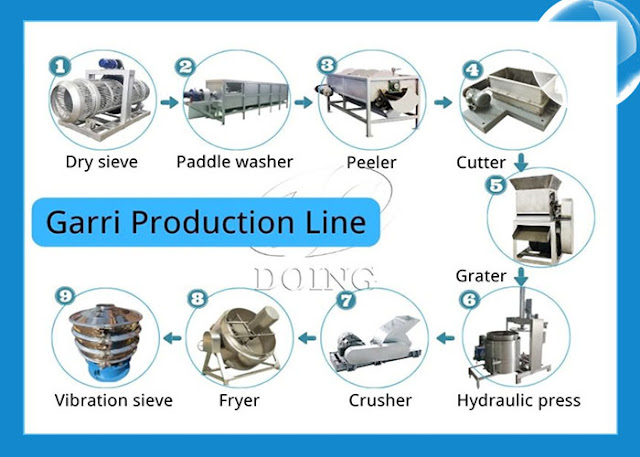

Garri processing machines

Selecting Premium Cassava Tubers: The Foundation for High Yield

The journey towards higher garri output begins right at the source - the selection of cassava tubers. High-quality raw materials are the bedrock upon which successful garri production is built. The type of cassava used can have a profound impact on the final output, making the choice of variety a critical decision.

- Utilizing High-Yielding Varieties: Opting for improved cassava varieties is a game-changer. These varieties are specifically bred to be resistant to common diseases that can decimate cassava crops, ensuring a more stable and abundant harvest. Moreover, they boast a higher starch content, which directly translates to more garri per tuber. By starting with these high-yielding varieties, processors set themselves up for success from the get-go, increasing the potential for a greater output in the garri processing stage.

Refining Garri Processing Techniques: Enhancing Efficiency and Quality

Once the right cassava tubers are sourced, the next crucial phase is the processing stage. This is where the raw cassava is transformed into the final garri product, and optimizing each step in this process can lead to significant improvements in output and quality.

- Mechanized Peeling: The traditional method of manual peeling is not only time-consuming but also labor-intensive. By introducing cassava peeling machines, processors can revolutionize this initial step. These machines can quickly and efficiently remove the cassava peel, reducing the time spent on peeling and allowing for a faster throughput of raw materials. This not only saves on labor costs but also enables the processing of more cassava in a shorter period, thereby increasing overall output.

- Advanced Grating: Investing in high-performance cassava grating machines is another essential step. These machines are designed to process cassava into a uniform mash with greater speed and precision compared to traditional grating methods. A consistent and well-processed mash is the basis for a high-quality garri product, and the efficiency of the grating process directly impacts how quickly the subsequent stages can be carried out, contributing to an overall increase in production output.

- Precise Fermentation Control: Fermentation is a critical process in garri production that affects both the quality and yield of the final product. Careful monitoring of the fermentation time is essential. Too short a fermentation period may result in an inferior product, while an extended period can lead to spoilage. By maintaining strict control over the fermentation process, processors can ensure a consistent quality of garri and minimize losses due to spoilage, ultimately maximizing output.

- Efficient Pressing: After grating, the cassava mash contains a significant amount of water that needs to be removed. Hydraulic pressers offer a highly efficient solution for this task. By effectively extracting water from the grated cassava, the drying time is significantly reduced. This means that the processed cassava can move on to the next stage of production more quickly, increasing the overall efficiency of the production line and enabling the processing of more cassava in a given time frame.

- Modern Frying Approaches: The traditional method of frying garri is often slow, labor-intensive, and may not always ensure consistent quality. Replacing these methods with mechanized fryers brings numerous benefits. Mechanized fryers can cook the garri more evenly and at a faster pace, improving both the taste and texture of the final product. Additionally, they offer better hygiene standards, reducing the risk of contamination and ensuring that the garri meets the highest quality requirements. This modernization of the frying process is a key factor in increasing production output while maintaining product quality.

Scaling Up Garri Production: Expanding Capacity for Greater Output

Garri production line

As the market demand for garri grows, scaling up production becomes necessary. This involves more than just increasing the quantity of raw materials processed; it requires a strategic investment in equipment and infrastructure to handle larger volumes of production.

- Boosting Processing Capacity: Investing in larger or additional garri processing equipment is a crucial step in scaling up production. Companies like Henan Jinrui offer a wide range of automatic and semi-automatic garri production equipment, with capacities ranging from 1 ton per day to 20 tons per day. This flexibility allows processors to choose the equipment that best suits their current and future production needs. By upgrading or adding to their equipment, processors can handle more cassava at once, significantly increasing the daily output of garri.

Optimizing Storage and Packaging: Protecting and Promoting the Product.png)

Garri making line

The final stages of storage and packaging are often overlooked but are equally important in ensuring a high output in garri processing. Proper storage and attractive packaging not only protect the product but also enhance its marketability.

- Appropriate Storage: Storing garri in airtight, moisture-proof containers is essential for maintaining its quality and extending its shelf life. Garri is highly susceptible to moisture, which can lead to spoilage and a reduction in product quality. By using the right storage containers, processors can prevent these issues, minimizing losses and ensuring that more of the produced garri reaches the market in good condition.

By implementing these comprehensive strategies, processors can effectively increase the output in garri processing. At the same time, maintaining strict quality control throughout the process ensures that the garri remains competitive in the market, leading to greater profitability. Henan Jinrui, with its extensive experience and expertise in cassava garri production equipment, has a branch office and factory in Nigeria, ready to support processors in their journey towards higher production output. If you are interested in learning more about cassava machines and how they can benefit your garri production business, please feel free to reach out to us at any time.

http://www.cassavaprocessing.com

WhatsApp/Phone: +8613526615783

Email:market@doinggroup.com

Comments

Post a Comment

Hi,write down you message,and let's talk according the difference.