What are the ways to improve the production efficiency of the flash dryer?

Cassava flour production has three parts: cleaning part, making part and drying part. Theoretically speaking, if you want to ensure the quality and efficiency of cassava flour products in cassava flour production, the primary improvement is the efficiency of the flash dryer. So how to improve the efficiency of the flash dryer in cassava flour production?

Two stages of flash dryer

Two stages of flash dryer

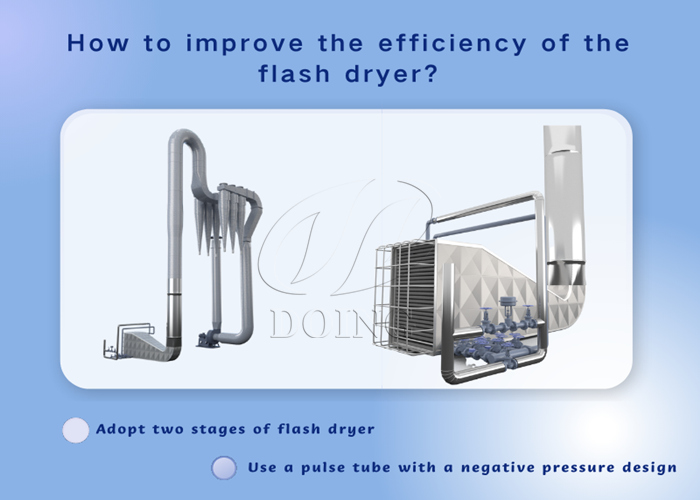

Adopt two stages of flash dryer

It is more difficult to dry cassava flour than any other starch product. Therefore, two stages of the flash dryer are necessary for cassava flour production. Firstly wet cassava flour will be sent into the first stage of the dryer by high-speed screw or winnow, and then cassava flour will be discharged from cyclones and be sent to the second drying system, and finally, dried flour will be discharged through cyclones. By two stages of drying of the flash dryer, cassava flour can be dried completely and production capacity can be ensured.

Steam boiler in flash dryer

Steam boiler in flash dryer

Use a steam boiler to improve heating efficiency

In addition, the radiator is heated by the air inlet of the flash dryer, and the equipment that provides the heat source for the radiator is also very important. Theoretically speaking, to ensure the quality and efficiency of cassava flour equipment products, the primary improvement is the heating efficiency. Normally hot air stove or steam boiler is suggested. Hot air stove is relatively cheaper, but it’s not easy to be controlled. While steam boilers can be well controlled, the price maybe a little higher. To get cassava flour with stable moisture content, it’s better to use a steam boiler.

Negative pressure pulse tube of flash dryer

Negative pressure pulse tube of flash dryer

Use a pulse tube with a negative pressure design

The last is the drying pipe design of the flash dryer in cassava flour production. Ordinary drying pipes adopt a vertical positive pressure design, but it is easy to cause uneven drying of cassava flour due to too short drying time. Therefore, if you want to ensure that cassava flour is dried evenly and takes a short time, you can use a pulse tube with a negative pressure design. The cassava flour stays in the drying pipe for a relatively long time, and it is not easy to leak, which ensures the drying efficiency in cassava flour production.

As a professional flour and starch processing machine manufacturer, Henan Jinrui Company can provide you with high-standard flash dryers. Our airflow dryer can not only be used for cassava flour production but also for cassava starch, potato starch, and sweet potato starch production.

Main features of the flash dryer of Henan Jinrui Company:

1. Suitable for heat-sensitive power or flake materials drying, fast drying speed.

2. Strictly control flash dryer technical parameters to ensure dried material meet requirements

3. Special cooling system is designed to guarantee that dried material has uniform moisture content.

4. Instant drying principle, the material is dried in 2-3 seconds, fast and convenient.

5. Adopting stainless steel material for the flash dryer to ensure final product quality.

This is the whole introduction of the flash dryer in cassava flour production. If you have the plan to set up a cassava flour processing line, you can contact our company.

Tel/Whatsapp: +86-13526615783

Website: http://www.cassavaprocessing.com

Email: sales@doingmachinery.com

Comments

Post a Comment

Hi,write down you message,and let's talk according the difference.