Configuration Analysis of Cassava Starch Processing Equipment Process Flow

The technology for cassava starch processing is very mature. But according to different raw materials, different starch quality requirements, and different investment budgets, the cassava starch processing equipment configuration can be quite different.

The basic cassava starch processing equipment procedures are raw cassava cleaning, washing, cutting, crushing, fiber separation, de-sanding, starch concentration and refining, dewatering, drying, and sieving.

Cassava starch processing equipment

Cassava starch processing equipment

Even though the configuration of cassava starch processing equipment may be different, it is necessary to ensure the effective separation of foreign contents and impurities, ensure final starch quality, and high starch yield, and reduce production costs.

Cassava starch processing washing equipment

Cassava starch processing washing equipment

1.Raw material acquisition and cleaning for cassava starch processing

Cassava tubers that are harvested from farms are attached to a lot of impurities, like stones, weeds, dirt, sand, etc. Before starch extraction, all these impurities need to be cleaned up. The cleaning process can be finished by machines like a dry sieve and paddle washer. But if the budget is small, people can also finish the cleaning by hand.

2.Material conveying device for cassava starch processing

In cassava starch processing plants, different conveying equipment are matched according to material forms. For example, a belt conveyor is used to transport cassava roots, a screw conveyor is used to carry small pieces of cassava after cutting, and a screw pump is used for slurry materials.

Crushing device equipment

Crushing device equipment

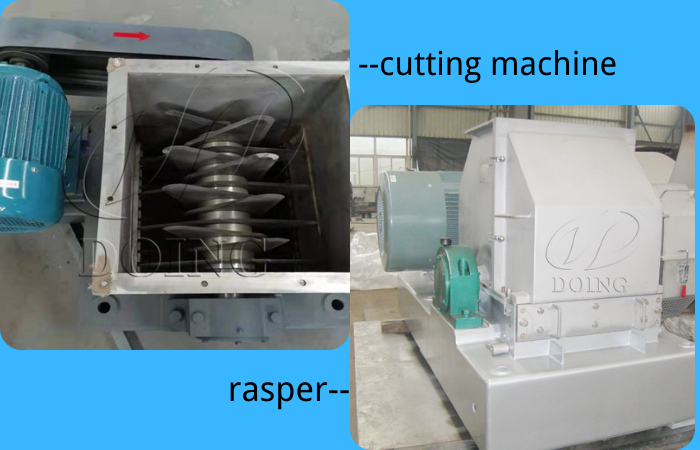

3.Crushing device for cassava starch processing

There are different crushing equipment for cassava starch processing. If one wants to start small, one small grater machine is enough. If the capacity is a little bigger, a hammer crusher is a good choice. While if one wants to set up a complete and huge capacity starch production line, the rasper machine is the best equipment that can ensure a high starch extraction rate.

4.Fiber separation for cassava starch processing

A rotary sieve machine is suggested for small scale cassava starch factories. It is easily operated and the price is cheap. And when capacity scales up, a multi-stage centrifuge sieve is recommended. Compared to the vertical type, the horizontal centrifuge sieve machine will have higher working efficiency.

Starch concentration and refining equipment

Starch concentration and refining equipment

5.Starch concentration and refining for cassava starch processing

In traditional cassava starch processing, people use the way of settling tanks to get pure starch. It is good when the capacity is small, but working efficiency is low. In modern processing way, 18-stage hycrocyclone stations are introduced to concentrate and purify starch milk. The hydrocyclone station from Henan Jinrui company has the function of concentration, refining, and recycling, ensuring high starch yield and high purification of final starch at the same time.

Starch dewatering and drying equipment

Starch dewatering and drying equipment

6.Starch dewatering and drying for cassava starch processing

After getting purified starch milk, the next is dehydration and drying of cassava starch. The peeler centrifuge will firstly dehydrate starch milk and get wet starch with a moisture content of around 38%, and then the flash dryer will be used to dry starch to make moisture content reduced to 12-14%. The moisture content can be controlled by adjusting equipment.

Configuration of cassava starch processing equipment can be adjusted according to the user’s requirement on starch quality and investment budget. If you have a plan to set up a cassava starch processing factory, feel free to contact Henan Jinrui company. Our project manager will work out a suitable solution based on your actual condition.

Tel/Whatsapp: +86-13526615783

Website: http://www.cassavaprocessing.com

Email: sales@doingmachinery.com

Comments

Post a Comment

Hi,write down you message,and let's talk according the difference.