What machine for make tapioca flour?

Tapioca as one of the popular crops in Africa has a high level of Nutrition and is popular in the local market. So some clients wonder how to make tapioca flour from raw tapioca. Here is some advice from Henan Jinrui Food Company:

Traditional and home-use method to process tapioca flour

Traditional and home-use method to process tapioca flour

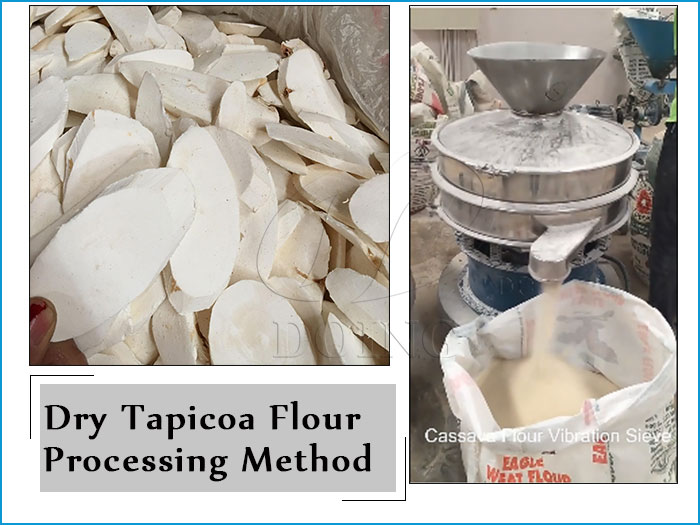

Tapioca flour processing includes 6 steps, including cleaning, peeling, cutting, boiling, drying, and milling.

Peeling: Peel thick layers with the peeling machine with high capacity.

Cutting: Cut peeled tapioca tubers into uniform size chips. This is to enable the chips to dry faster at the same time and temperature.

Boiling: After cutting, put tapioca chips in boiling water for about 5 minutes. If possible need a longer time.

Drying: Put chips in a cabinet dryer. Ensure tapioca chips are properly dried.

Milling: Mill dried tapioca chips into fine flour using a hammer mill.

After finishing these steps, you can do a sieve and package.

This is the traditional and home-use method to process tapioca flour. In high capacity tapioca flour processing, we advise processing fresh tapioca tubers by machinery. From cleaning, and peeling layers, then grating to mash, desanding, removing moisture, and finally drying by flash dryer to get dry tapioca flour.

Following is the way how is tapioca flour processed with a tapioca flour processing machine:

Tapioca flour processing machine

Tapioca flour processing machine

a. Tapioca cleaning and peeling: First, the tapioca is transported to the factory by a forklift and put into the conveyor. The Dry sieve and paddle washer will work together to maximize tapioca cleaning affection. Thereby reducing the generation of impurities during the post-processing. The tapioca is then sent to a high-efficiency peeler to remove the two outer skins.

b. Tapioca grinding: Put peeled tapioca into a cutter to cut small pieces. Then use a rasper machine to break the tapioca into a slurry at high speed.

c. Tapioca flour dewatering: Use the high-strength filter press automatically dewatering to better match the post-drying process.

d. Tapioca flour drying: Put the dewatered tapioca pulp into the flash dryer with instant drying ability. It is beneficial to improve the processing efficiency of tapioca flour.

e. Tapioca flour sieving: Use a vibration sieve or sifter sieve to get high quality tapioca flour.

Henan Jinrui Food Company has done machine manufacture for more than 12 years, not only tapioca flour processing machinery but also other cassava processing machines. If you have an idea to learn more machine details, you can message us, our project manager will contact you soon.

Tel/Whatsapp: +86-13526615783

Website: http://www.cassavaprocessing.com

Email: sales@doingmachinery.com

Address: 19B Kudirat Abiola Way Olusosun Bus stop, Ikeja, Lagos, Nigeria

Comments

Post a Comment

Hi,write down you message,and let's talk according the difference.