Large-Scale Potato Starch Processing Machinery Recommendation

For large-scale potato starch processing, wet process technology remains the industry standard for achieving high starch yield, purity, and processing efficiency. This method, which separates starch granules from potato cells in a water-based system, is particularly suited for automated processing lines handling 20 tons or more of raw potatoes daily. Below is an overview of the essential equipment required for a fully integrated, large-scale potato starch processing line.

Essential Equipment for an Automated Potato Starch Wet Process Line

1. Raw Material Handling and Washing Unit

Primary Function: Removal of soil, stones, and organic impurities from raw potatoes.

Key Equipment:

Dry Sieve: Handle large impurities like soil, stones, leaves on raw potatoes.

Rotary Washer: Provide thorough scrubbing and washing potatoes through rotational movement in a water medium.

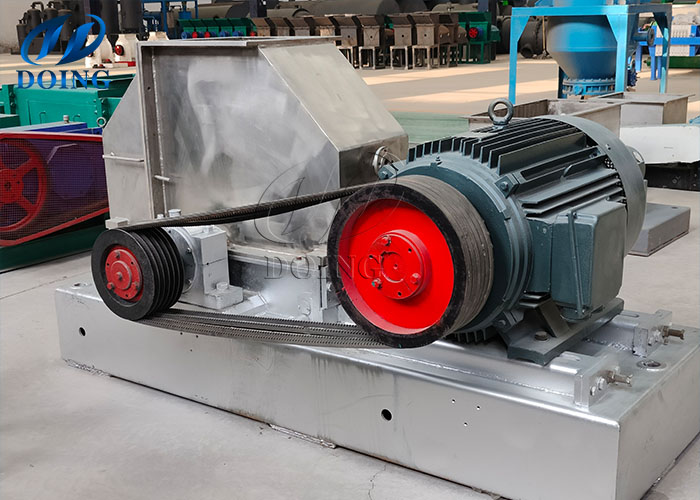

2. Cutting and Grinding Unit

Primary Function: Disintegration of potato tissue to release starch granules.

Key Equipment:

Cutting Machine: Cut potatoes into small pieces convenient for further grinding

High-Capacity Raspers: Feature specially designed saw blades to create uniform pulp consistency while maximizing potato starch release.

cassava rasper

cassava rasper

3. Starch Extraction and Separation Unit

Primary Function: Separation of potato starch milk from fibrous pulp.

Key Equipment:

Centrifugal Sieve: Multi-stage screening systems that separate potato starch from fiber through counter-current washing principles.

4. Starch Purification Unit

Primary Function: Further removal of residual impurities like proteins and cell saps and other soluble components.

Key Equipment:

Desanding Cyclones: Specifically designed for removing mineral impurities.

Multi-Stage Hydrocyclone Stations: Provide efficient washing and concentration of starch. Refine starch milk by removing proteins and fine impurities through density-based separation.

hydrocyclone station

hydrocyclone station

5. Dewatering Unit

Primary Function: Reduction of moisture content in purified potato starch slurry.

Key Equipment:

Vacuum Filtration Units: Employ vacuum pressure to extract water from starch slurry, forming a moist cake with reduced moisture content of 40%.

6. Drying System

Primary Function: Final moisture reduction to meet commercial standards.

Key Equipment:

Flash Dryer: Utilize rapid hot air exposure to efficiently dry starch particles without compromising quality. Normally the moisture of dry potato starch is about 12-14%

Cooling Conveyors: Stabilize potato starch temperature post-drying.

flash dryer

flash dryer

7. Finishing and Packaging Unit

Primary Function: Preparation of qualified potato starch for storage and distribution.

Key Equipment:

Milling and Sieving Systems: Ensure uniform particle size distribution.

Automated Packaging Machines: Provide precise weighing and packaging operations.

Technical Advantages of Potato Starch Wet Process Technology

Enhanced Starch Recovery: Achieves superior extraction rates through comprehensive cell rupture and counter-current washing.

Consistent Quality Output: Multi-stage refining ensures high purity and uniform product characteristics.

Processing Efficiency: Continuous operation capability supports high-volume throughput requirements.

Resource Optimization: Closed-water systems minimize fresh water consumption through sophisticated recycling.

The wet process technology, incorporating specialized equipment from initial washing through final drying, represents the optimal solution for large-scale potato starch processing. Tell us your capacity, Henan Jinrui's engineers will design a tailed equipment design!

WhatsApp/Phone: +8613526615783

http://www.cassavaprocessing.com

http://www.cassavaprocessingplant.com

http://www.cassavastarchmachine.com

http://www.starchprojectsolution.com

Email:market@doinggroup.com

Comments

Post a Comment

Hi,write down you message,and let's talk according the difference.